Splice connectors is the name given to plastic clips, the purpose of which is to make quick connections – or splices – between at least two pieces of wire. Splice connectors are designed to be used with electrical cables, electrical device wires and telephone cables.

A splice connector is made up of a plastic clip that comes with a sharp metal insert that is able to safely cut the plastic insulating jackets of multiple wires and then crimp them together. The clip on the splice connector then snaps into place and hold the wires securely together. Splice connectors can be used for splicing wires without the need for them to be soldered.

It can actually be quick and easy to learn how to splice electrical wires but it is very important to know how to do so in the correct manner, or the electrical system will end up being both unreliable and unsafe, resulting in the risk of electrical shocks or even fires.

It is vital to create splices that are safe and secure enough that they will be able to create a fine electrical and mechanical joint that has enough strength to avoid being pulled apart and is tight enough to avoid any loss of electrical voltage.

The first step

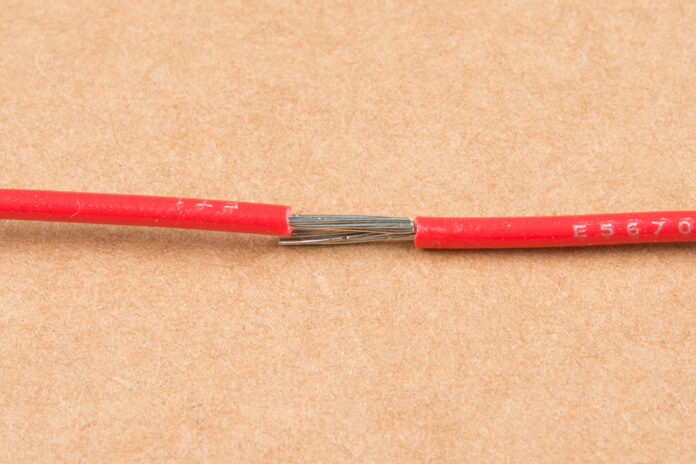

The first step is to strip away an inch of the inner foil shield and insulation jacket from the end of the cables that you are intending to splice together. The interior individual wires which are just covered with coloured plastic insulation jackets should be left alone.

The second step

An individual interior wire from one of the cables needs to be inserted inside the splice connector’s wire hole, with the end being pushed in all the way. The majority of connectors have a clear side that enables you to check whether or not the wire has actually been fully inserted. The same coloured wire from the opposing cable should then be inserted into the splice connector’s other wire hole.

The third step

The next step is to have the splice connector be set into the jaws of pliers, and then use them to apply firm pressure in order to snap together the splice connector’s top and bottom. The splice connector can cut through those wires and have them clamped together for the creation of a secure splice connector. This process can then be repeated with the other wires from the different cables.

The final step

A plastic zip tie should be used in order to have the spliced cables secured together to ensure the spliced connections cannot be pulled apart. The zip tie should be wrapped around the bottom end of both cables’ stripped insulation jacket and tied off. The end of the zip tie can then be trimmed down with the use of scissors.

Using a Quick Splice connector from RS Components or other popular retailers, is the quickest and easiest way to splice electrical wires, but still needs to be done in the correct manner so as to ensure both efficiency and safety.